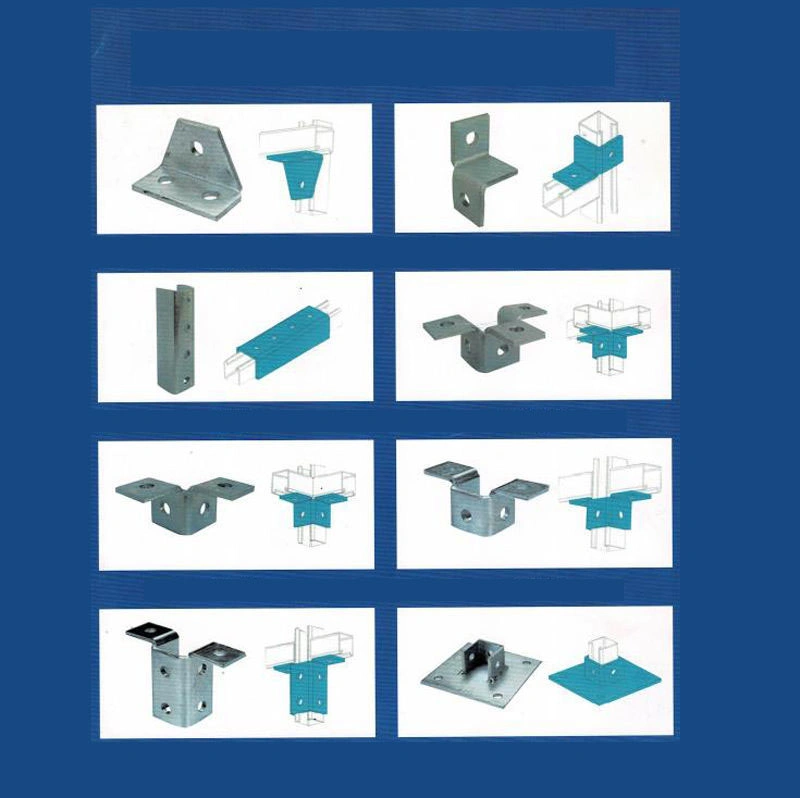

Channel Steel Gusset Plate / Section Steel Huasi/ Seismic Support Connector

Seismic support Pipes Anti Seismic Bracing Support System Flat washer Channel Steel Gusset Plate / Section Steel Huasi/

Basic Info

| Model NO. | GB ISO |

| HS Code | 7610900000 |

| Production Capacity | 2000tons/Month |

Product Description

Seismic support Pipes Anti Seismic Bracing Support SystemFlat washer Channel Steel Gusset Plate / Section Steel Huasi/ Seismic Support Connector

product paramaters

| Product Name | Seismic Bracing Support System / Anti-Vibration Mounts |

| Material | Q235B,Carbon steel or SS304 or SS316 |

| Surface Treatment | HDG(hot dipped galvanized ),Pre-galvanized,powder coating (Black,Green,White,Grey,Blue)etc |

| Working Pressure | 300 PSI/2.07 Mpa |

| Technique | Stamping, Cold Forming |

| Packing | Shrinking Film/Carton/Wooden Pallet |

Product Description

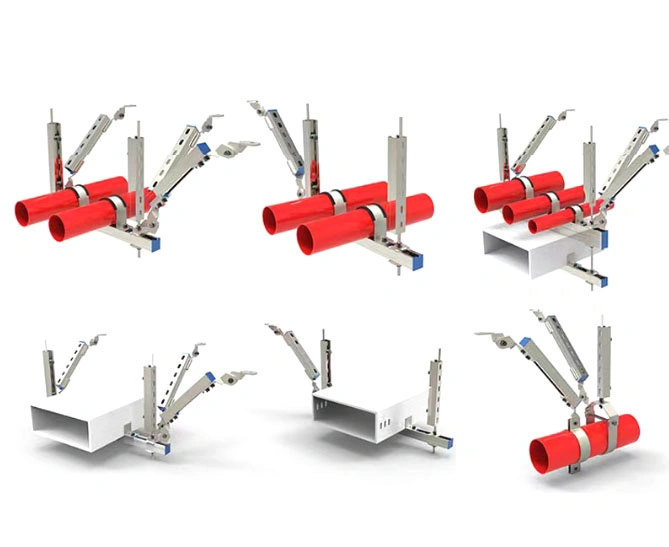

Sesmic Bracing systems are specifically designed and engineered to brace and secure suspended non-structural equipment (VAV boxes, fans, unt heaters, small in-line pumps, etc.) and components ( HVAC duct, conduit/ cable tray, and piping) within a building or structure to minimize damage from an earthquake or seismic event.Application1) Air conditioning/ventilation/fire fighting piping system2) Commercial/Iindustrial building, factory, shopping mall, school, bridges,etc.3) Power station, field operation and some huge engineer construction.

Features

1, Simple design process and superior products reduce costs in design, materials and installation.2, Each working procedure can be crossed to shorten the construction period effectively. 3, Highly corrosion resistant surface treatment.4, Make full use of the site space, the pipeline arrangement is neat and beautiful. 5, The stress of the system pipeline is stable, and the cost of operation and maintenance in the later period of the system is effectively reduced.

| Performance comparison between traditional and new seismic support bracing system | ||

| Types | Traditional support system | New Seismic support bracing system |

| Installation | Raw materials need cutting, welding, painting etc., complication operation causing high labor cost and longer operation time | No cut, no weld, no painting, easy installation. |

| Quality | The procedures of cutting and welding is determined by the ability of the labors, no unified standard | All the components are produced by automotic machines with strict standard and high quality inspection requirement |

| Appearance | No professional installation drawing design to guide, the job site is disorderly | Adopt comprehensive design, the job site is neat and beautiful |

Seismic support Pipes Anti Seismic Bracing Support System

| Product Name | Seismic Bracing Support System / Anti-Vibration Mounts |

| Material | Q235B,Carbon steel or SS304 or SS316 |

| Surface Treatment | HDG(hot dipped galvanized ),Pre-galvanized,powder coating (Black,Green,White,Grey,Blue)etc |

| Working Pressure | 300 PSI/2.07 Mpa |

| Technique | Stamping, Cold Forming |

| Packing | Shrinking Film/Carton/Wooden Pallet |

Product Description

Sesmic Bracing systems are specifically designed and engineered to brace and secure suspended non-structural equipment (VAV boxes, fans, unt heaters, small in-line pumps, etc.) and components ( HVAC duct, conduit/ cable tray, and piping) within a building or structure to minimize damage from an earthquake or seismic event.Application1) Air conditioning/ventilation/fire fighting piping system2) Commercial/Iindustrial building, factory, shopping mall, school, bridges,etc.3) Power station, field operation and some huge engineer construction.

Features

1, Simple design process and superior products reduce costs in design, materials and installation.2, Each working procedure can be crossed to shorten the construction period effectively. 3, Highly corrosion resistant surface treatment.4, Make full use of the site space, the pipeline arrangement is neat and beautiful. 5, The stress of the system pipeline is stable, and the cost of operation and maintenance in the later period of the system is effectively reduced.

| Performance comparison between traditional and new seismic support bracing system | ||

| Types | Traditional support system | New Seismic support bracing system |

| Installation | Raw materials need cutting, welding, painting etc., complication operation causing high labor cost and longer operation time | No cut, no weld, no painting, easy installation. |

| Quality | The procedures of cutting and welding is determined by the ability of the labors, no unified standard | All the components are produced by automotic machines with strict standard and high quality inspection requirement |

| Appearance | No professional installation drawing design to guide, the job site is disorderly | Adopt comprehensive design, the job site is neat and beautiful |

Company Advantages:

1. OEM/ODM services are available

2. Strict QC inspecting rules: all products must be 100% inspected before delivery.

3. Large production capacity, fast delivery.

4. Prompt quotation for your inquiry

5. Quality,reliability and long product life.

6. Professional manufacturer offers competitive price.

FAQ

Q1. What is your main products?

A: Fasteners, Anchor bolt and washer.

Q2: How long is your delivery time?

A: It depends on whether we have stock, if we have stock products, we can delivery in 2 days after receive the payment. And normally our production time is in 15-20 workdays for one container (20-26 ton).

Q3: What s your after-sale service?

A: We produce your order strictly by your request.The product is remanufactured after sample confirmation. If there is quality problem. please provide photos or test reports, we will replace defective goods or return funds

Q4;What is your payment term?

A: Mostly we use 30% advance payment by T/T, 70% before shipment.For small amount order, we have paypal account.

Q: How can I get the quotation?

A: Please send us information for quote: drawing, material, weight, quantity and request,we can accept PDF, ISGS, DWG, STEP file format.

If you don't have drawing, please send the sample to us,we can quote base on your sample too.

Send to us